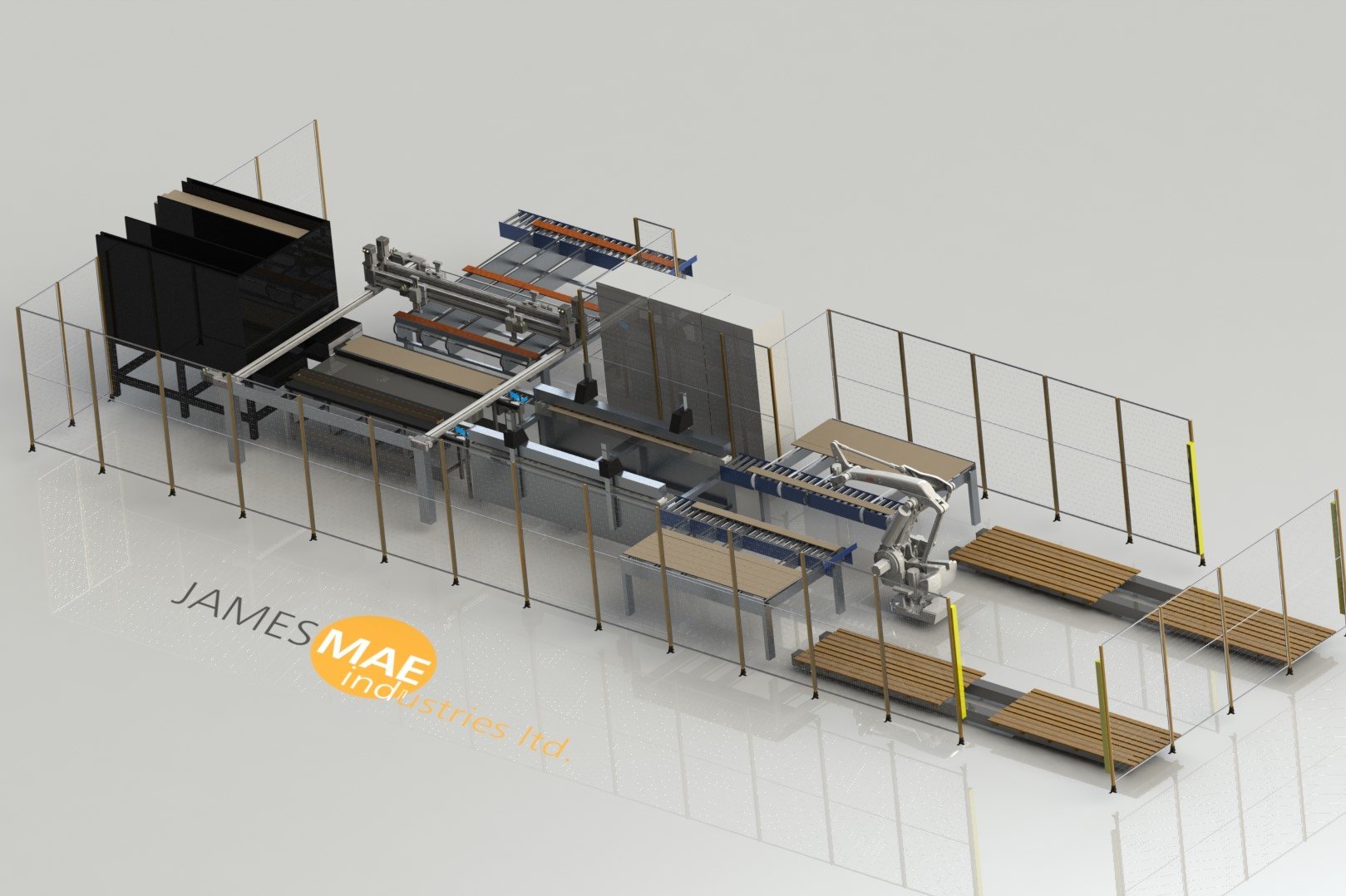

Our Automation division specialises in the design, development and manufacturing of custom automation & robotics for a wide variety of industry sectors. Our inhouse services offer the highest standards of design, manufacturing capability and technical skills.

Whatever your product or pack handling requirement, we can provide an innovative cost effective automation solution. We are able to offer standard designs or a bespoke package to exacting requirements.

We have over 40 years’ experience in design and delivery of automation & robotic systems and a large installed base of equipment in many Blue chip businesses. We can call on the experience gained in these applications in development of new solutions to meet the latest automation challenges.

Our skilled and professional design team provides a complete design and engineering service, including; Concept and design calculations, Mechanical design & detailed drawings, Electrical / controls design, Risk assessment, CE Marking and Project Management.

We use the latest Solid works 3D computer aided design technology which delivers better design visualisation, reduced lead times and improved drawing quality and documentation, to ensure a “right first time” mentality to every project.

Sectors

Tertiary (Transit) Packaging

Special Purpose Automation

What ever the application, we can deliver.

Designing and manufacturing a bespoke solution is very different to the selection, purchase and delivery of a standard machine purchased from a supplier catalogue.

For new projects with particularly challenging requirements, it can be required to conduct a proof of concept phase before a full-scale design and build, to demonstrate the solution to an identified technical risk. A proof of concept phase “de risks” the project by identifying and proving the solution to a challenging problem.

The identified technical solution is then built into a detailed project plan and together, these items form the core of a costed automation proposal. It is vital this level of analysis, design, and planning is performed up-front to help minimise the risk of unacceptable project slips or inability to meet the machine capability requirements.

Many different skills are necessary for seeing this done successfully, across multiple remits – such as sales, engineering and project management – and it’s these in house capabilities and over 40 years of experience which make James Mae Group a safe pair of hands for the development of special purpose automation.

Primary Packaging

Specialists in packaging automation.

Sometimes described as “picking”, primary packaging is described as - An unwrapped (naked) product off a production line of any type needs to be primary packaged in some way. It is the first packaging layer in which the product is contained. This packaging is used to contain, preserve, protect and inform the end user. Products can be primary wrapped in a number of different ways from flow-wrapped film to pre-formed or thermoformed trays. (amongst many others).

With the introduction of high speed pick and place robotics and vision technology over the last 15 years. All types of naked products can be automatically handled and placed in different types of primary packaging machinery systems such as flow-wrappers, tray sealers, de-nesters and thermoformers. Any product can be picked from enrobed, frozen, baked, raw, fried, fresh, to work in progress. Products can be unscrambled from bulk at high speeds and with the addition of the latest innovations in vision technology products can also be quality controlled before being placed for primary wrap.

With a number of different robotic and vision system manufacturers in our portfolio, any speed or production application / environment can be catered for. James Mae Group has over 40 years of experience in delivering quality systems to this sector.

Secondary Packaging

In a James Mae automated solution, any type of pre packed product in all types of packaging styles can be handled.

Sometimes described as “packing”. Secondary packaging is described as the packaging used to group various pre-packaged (primary wrapped) products together. This packaging is additional to the primary packaging and that is used for protection and collation of individual units during storage, transport and distribution. They can be used in some sectors to display primary packs on shelf. Sometimes called grouped or display packaging. This category also includes packaging purposely made to display multiple product units for sale, in order to speed restocking from storeroom to shelf. Also know as retail-ready packaging (RRP), shelf-ready packaging (SRP) or counter-top display units (CDUs). This packaging medium can be a carton, case or food tray or shrink-wrapped tray (amongst many others)

In a James Mae automated solution, any type of pre packed product in all types of packaging styles can be handled, collated and if required, buffered. Our integrated custom carton / tray erectors / de-nesters can produce and load all types of packaging mediums to a secondary packaging system.

Our custom closing systems can tuck, fold and can use glue or tape to close any packaging style. Visions systems are available to QC finished packs. Our flexible systems can be quickly and simply changed without tools to other required packaging types.

With a number of different manufacturers pick, place and heavy duty multi axis robots available in our portfolio, any speed or production application can be catered for. Product can also be automatically quality checked as part of a system prior to loading.

James Mae Group has over 40 years of experience in delivering quality systems to this sector.

Custom Robotics

James Mae has extensive experience working with many leading third-party robot suppliers.

James Mae group has a range of robotic solutions to offer, all with maximum flexibility and reconfigurability to suit their purpose. Typical robot solutions –

High speed pick and place using delta or Scara robots

Packing, palletising and de-palletising using four and six axis robots

General industrial robotics

Cutting and slicing

James Mae has extensive experience working with many leading third-party robot suppliers such as (but not limited to) ABB, Fanuc, Kuka, Staubli, Schneider and Yaskawa enabling us to match a clients preferred supplier. If such a requirement doesn’t exist, we are able to select the best robotic fit for the application.

Its also possible to offer full simulation services to prove the system architecture is correct before setting to work.

Collaborative Robots

James Mae group has a over 40 years experience in robotics and can advise on the application and use of collaborative robots.

A cobot or collaborative robot is a robot intended to physically interact with humans in a shared workspace without the requirement for safety interlocked guarding. The robots are designed to run at a speed and force that will not injure an operator in an unintended collision.

This is in contrast with all industrial robots, designed to operate autonomously at high speed inside a locked safety enclosure. Operators are not allowed inside the guarding of an industrial robot and suppliers go to great lengths to ensure the safety systems cannot be defeated protecting from any potential injury.

Only one kind of collaborative robot can be used without any additional safety features (Power and force limiting). According the international standards ISO 10218 part 1 and part 2, but there are four types of collaborative features for robots.

Safety Monitored Stop

Hand Guiding

Speed and Separation Monitoring

Power and Force Limiting

James Mae group has a over 40 years experience in the design and manufacture of automation and can advise on the application and use of collaborative robots.

Conveyor Systems

James Mae design, and manufacture all types of conveyors.

James Mae Group provide a wide range of conveyor types either as standalone individual units or integrated into a fully automated system. Typical types of conveyor include:

Flat belt

Powered belt bends

Pallet handling rollers

Straight running plastic modular

Curved plastic modular

Powered roller

Wire belt

Spiral elevating and de-elevating with cooling functions

Cutting Automation

James Mae has automated cutting technology that can be applied to almost any area.

Food products are very often produced in a way that requires them to be cut or portioned. This could be sweet products which are made into bars or bite sized pieces, cakes that need to be sliced before filling or fruit and vegetable produce that need to be peeled, trimmed or portioned prior to packaging. James Mae has automated cutting technology that can be applied to all of these areas. Typical technologies include:

Reciprocating blades

Continuous bandsaws

Static blade

Rotary blades, plain or serrated

Ultrasonic

High Pressure water jet (typically ay 4,000 bar or 55,000 psi)